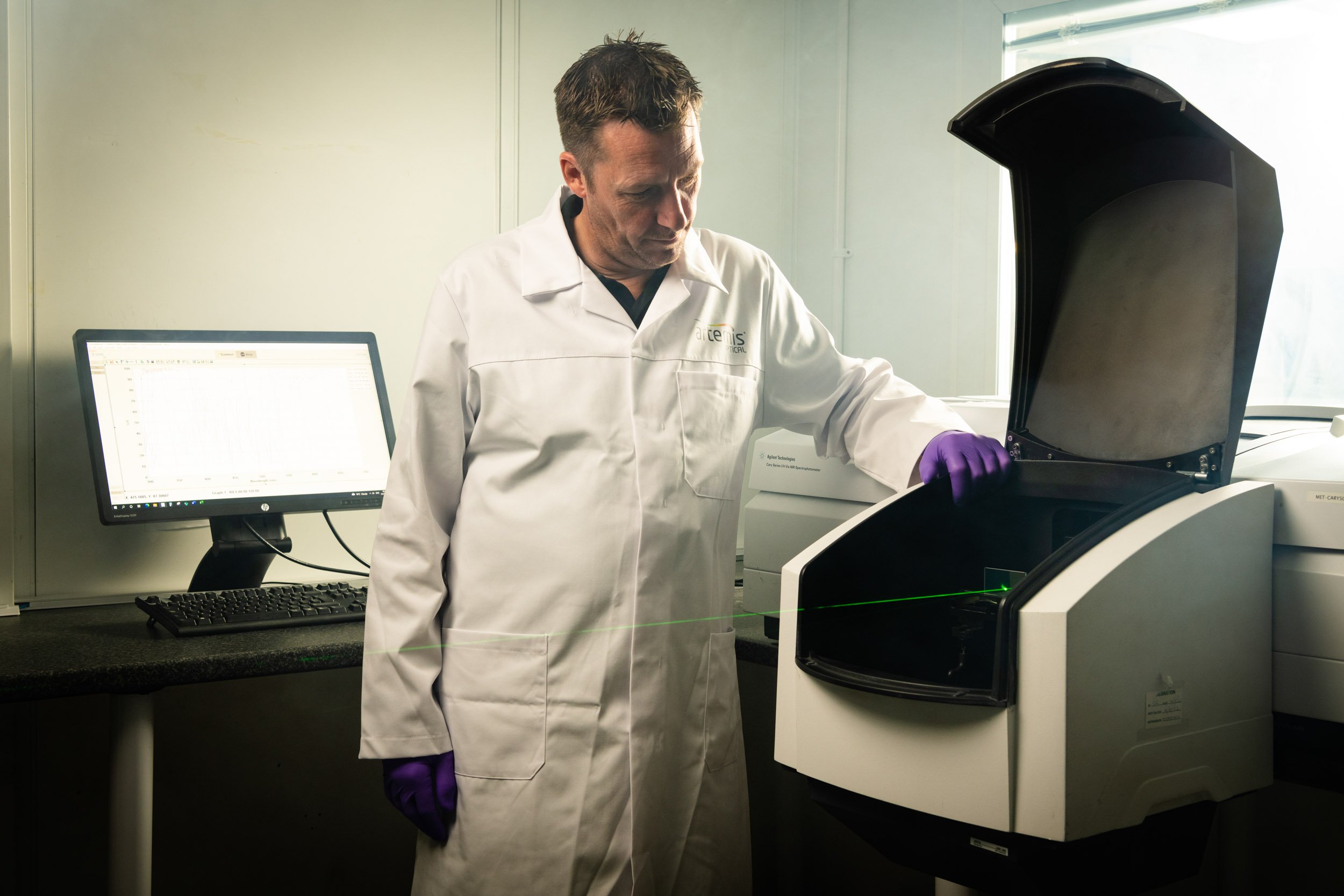

Our Facilities

At our state-of-the-art optical thin film coatings facility, we utilise cutting-edge deposition technologies

This sophisticated equipment enables us to create exceptionally precise and high-quality optical coatings, tailored to meet the most demanding requirements across a wide range of applications, including telecommunications, aerospace, and defence industries.

Facility:

2,000 square metre (21,500 square feet) custom-built premises

1,500 square metre (16,100 square feet) environmentally controlled production laboratory

Six main coating chambers

Opto-mechanical assembly line

State-of-the-art metrology laboratory

Assembly cleanroom facility

Bespoke head-up display combiner measurement system

Coating Equipment:

3 Leybold APS1104

2 Leybold Syrus LC3

All plants equipped with Quartz Crystal Monitoring.

x E-Beam guns.

All plants have an Advanced Plasma Source (APS)

IR plants have additional Thermal sources.

Optical monitoring available on two plants.

Bespoke grading mechanism for Colour Selective combiner plates.

New Chamber with IR capability planned for 2024.

1 bespoke DLC (diamond-like-carbon)

Spectrophotometers:

2 x Cary 5000 UMA – UV VIS NIR 175nm – 3300nm. Variable angle (S+P) reflection measurement capability.

1 x Cary 6000i UV VIS NIR 175nm – 1800nm. High resolution OD measurement capability. OD 8.

2 x Cary 60 with colour IVPT capability 190nm – 1100nm.

1 x Perkin Elmer Frontier Optica FTIR 1.2µ - 30µ

1 x Fully Automated OD Laser Test Facility @ 694nm 0° - 80° with built in Cary 60 for Colour/IVPT measurement.

1x Combiner Test Station – Automated angular measurements with X Y Z staging and integrated Cary 60.

Optical Test:

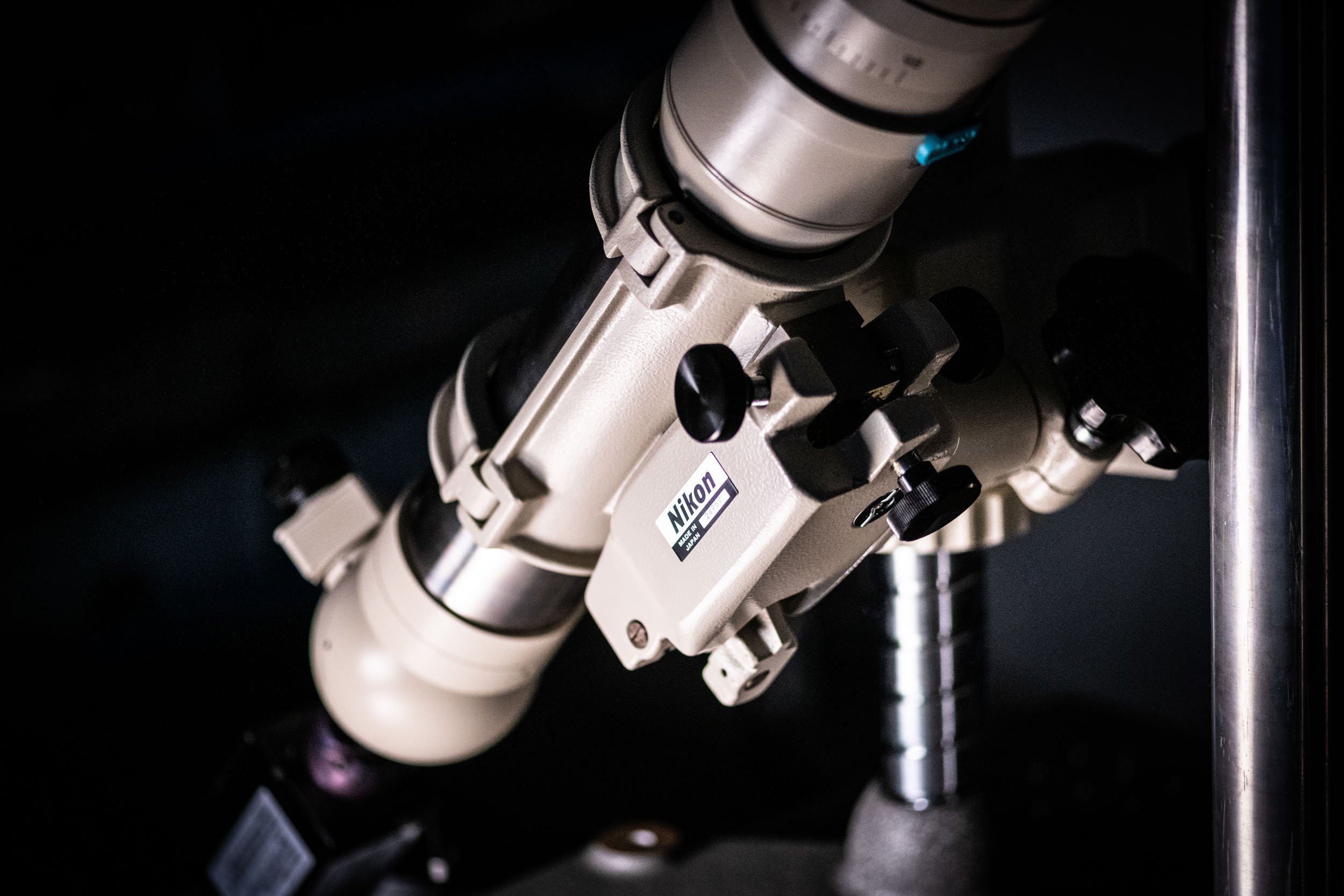

Fisba µPhase Interferometer 633nm. (max Diameter 100mm). Capable of measuring Form Error, Transmitted Wavefront Error and Parallelism of flat substrates.

Environmental Testing:

ETS Humidity test chamber – configured for standard humidity test (49°C, 95% Relative Humidity)

DSE Climatic test chamber - +10°C to +95°C, 10 - 98%RH

DSE Temperature test chamber - -70°C - +180°C

Ascott Salt Fog Chamber

Abrasion Testing

Eraser abrader conforming to MIL-E-12397

Wiper abrader conforming to TS1888 para 5.4.3 (5 mins @ 1000 rpm)

Inspection

Calibrated scratch/dig reference samples

ASH OMNI 3 Digital microscope and measurement system

Dynascope 5-axis Measurement system

Resistance

Jandel 4-point probe Ω/sq

Thin Film Design

Design Software

Film Star

Optilayer

Artemis proprietary software for design and simulation of dual HUD combiner systems

3 x Optical Thin Film Designers

2 x Process Engineers

2 x Manufacturing Engineers

1 x Test Engineer

Exceptionally precise and high-quality optical coatings